Ball testing key benefit for USBC members

August 02, 2012

ARLINGTON, Texas - Each year, hundreds of new bowling balls are put on the market and before they reach consumers, prototypes are inspected thoroughly by the United States Bowling Congress to ensure they meet specific standards.

The USBC Equipment Specifications team has developed a battery of tests to make sure every bowling ball that makes it to the consumer market is legal based on USBC rules.

The USBC Equipment Specifications team has developed a battery of tests to make sure every bowling ball that makes it to the consumer market is legal based on USBC rules.

"Sometimes people ask what they get for their USBC membership, and this is one of those behind-the-scenes things we do for our members," USBC Managing Director of National Governing Body Neil Stremmel said. "The tests that we do on new bowling balls help protect our members from wasting their hard-earned money on bowling balls that could potentially not work as advertised."

An example of why tests on new bowling balls is so important recently was uncovered at USBC Headquarters earlier this year when an international manufacturer submitted balls that did not meet proper standards and was not approved.

The manufacturer submitted several samples of the new ball, all of which were identical on the outside, but the cores of the balls were where the problems began.

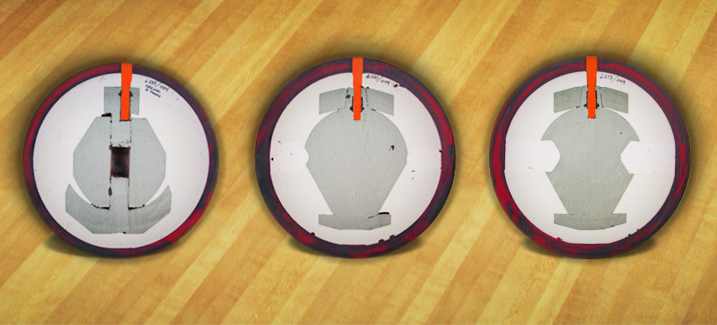

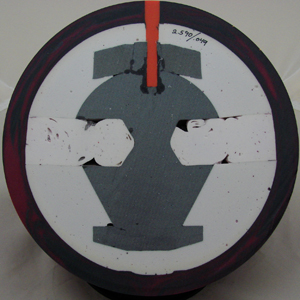

After performing tests on the balls and coming back with head-scratching results, the USBC Equipment Specifications team cut each of the bowling balls in half and the results were shocking.

The same ball had two main core shape differences and five modified versions of the two main cores. The serial numbers on the balls were sequential, which means the balls should have come out of the production line in order.

"Had this ball not been further scrutinized, there would be no way to know what the end user was getting," Stremmel said. "The ball also would have been subject to cracking and core separation with the large void in the core.

"This is just one example of how we protect USBC members by doing what we do. Nobody wants to spend $200 or more on a ball and not know if they're getting a quality product, or a product that is similar to all of the other balls of the same model."

Stremmel said that without the approval process the danger is that a bowler could purchase this ball and wanted to compliment it with one like it, which would be impossible. The ability to consistently manufacture the bowling ball the same way each time is critical.

"If a bowler went out and bought this ball and their friends liked it and wanted one that reacts similar, it would be impossible and they would end up wasting their money," Stremmel said. "Or worse yet, if someone were new to bowling and purchased a bowling ball like this that would not react properly, they may quit the sport."

USBC Research Technician Jason Milligan said noticing the difference between the balls is important because it assures there will be consistency in the products available to consumers.

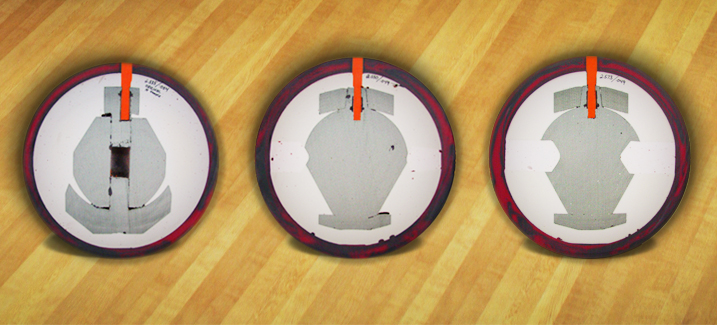

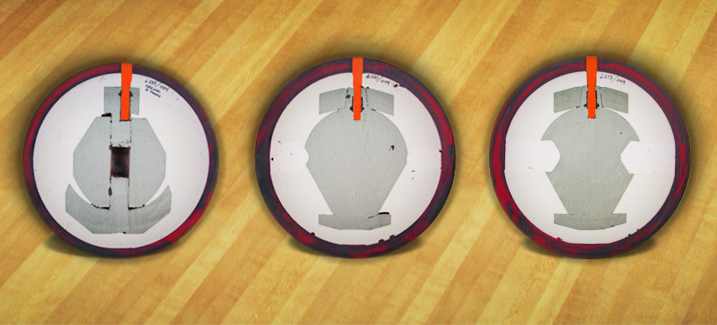

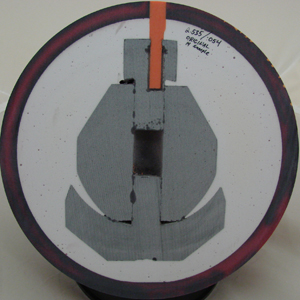

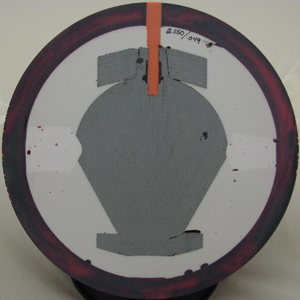

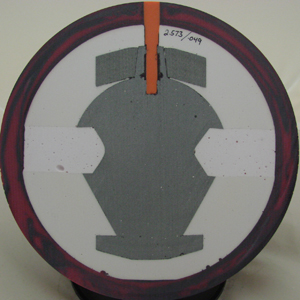

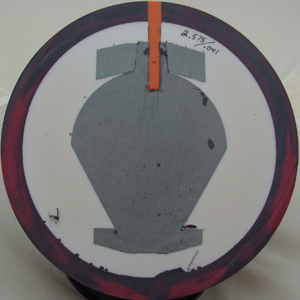

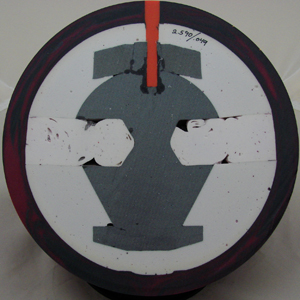

Milligan offered the following descriptions that go along with photos of the inside of each ball that was tested.

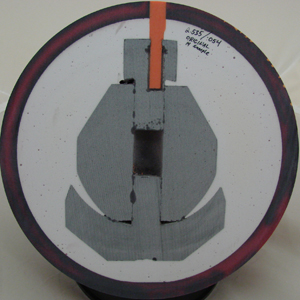

Original Sample - RG 2.534"/Differential .054" - "This ball has a large void in the center of the inner core, which is not allowed. Other than that, the core shape has not been altered, and this ball would otherwise be allowed. All manufacturing requirements can be found in the USBC Equipment Specifications Manual."

Original Sample - RG 2.534"/Differential .054" - "This ball has a large void in the center of the inner core, which is not allowed. Other than that, the core shape has not been altered, and this ball would otherwise be allowed. All manufacturing requirements can be found in the USBC Equipment Specifications Manual."

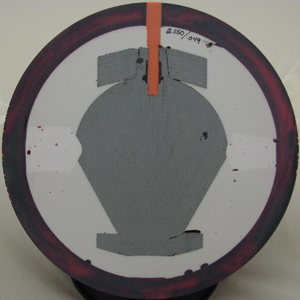

Additional Sample A - RG 2.550"/Differential .049" - "This ball shows an entirely different inner core shape from the original sample. This shape has a higher RG and lower differential, which should result in not as much hook potential with all other things being considered equal. Also, there have been modifications to the outer core by drilling into it and filling it with a different density material."

Additional Sample A - RG 2.550"/Differential .049" - "This ball shows an entirely different inner core shape from the original sample. This shape has a higher RG and lower differential, which should result in not as much hook potential with all other things being considered equal. Also, there have been modifications to the outer core by drilling into it and filling it with a different density material."

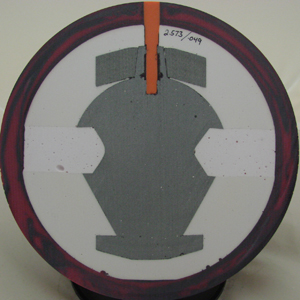

Additional Sample B - RG 2.573"/Differential .049" - "This inner core shape is similar to Additional Sample A, but with a larger modification to the outer core. The modifications also raised the Low RG values, which should result in the ball not picking up a roll as soon as the other two balls mentioned."

Additional Sample B - RG 2.573"/Differential .049" - "This inner core shape is similar to Additional Sample A, but with a larger modification to the outer core. The modifications also raised the Low RG values, which should result in the ball not picking up a roll as soon as the other two balls mentioned."

Additional Sample C - RG 2.568"/Differential .044" - "This inner core shape is similar to Additional Samples A and B but only has one modification to the outer core. This ball would have a little less hook potential compared to Additional Samples A and B and significantly less when compared to the original sample."

Additional Sample C - RG 2.568"/Differential .044" - "This inner core shape is similar to Additional Samples A and B but only has one modification to the outer core. This ball would have a little less hook potential compared to Additional Samples A and B and significantly less when compared to the original sample."

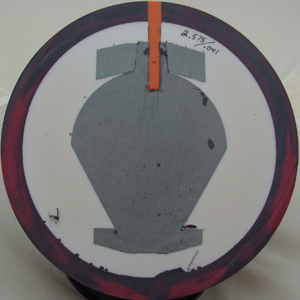

Additional Sample D - RG 2.575"/Differential .041" - This ball appears to have the same inner core shape as Additional Samples A, B and C. However, this core doesn't show any modification to the outer core and with the .041" of differential it would have the least amount of hook potential of any of the samples so far."

Additional Sample D - RG 2.575"/Differential .041" - This ball appears to have the same inner core shape as Additional Samples A, B and C. However, this core doesn't show any modification to the outer core and with the .041" of differential it would have the least amount of hook potential of any of the samples so far."

Additional Sample E - RG 2.590"/Differential .049" - "This ball has the same inner core shape as the other additional samples listed so far but with the largest modification to the outer and inner core. In fact, the material used to fill in the holes drilled for modification hardened before it could fill the holes completely resulting in voids, which are not allowed. This ball has the highest Low RG value of any of the balls tested and would have the most delayed reaction of any of the balls shown."

Additional Sample E - RG 2.590"/Differential .049" - "This ball has the same inner core shape as the other additional samples listed so far but with the largest modification to the outer and inner core. In fact, the material used to fill in the holes drilled for modification hardened before it could fill the holes completely resulting in voids, which are not allowed. This ball has the highest Low RG value of any of the balls tested and would have the most delayed reaction of any of the balls shown."

Additional Sample F - RG 2.535"/Differential .055" - "This is the only additional sample with the same core shape as the original sample. If you look closely, you can see that there were modifications made to this outer core as well. The RG values show us this ball should be very similar to the original sample performance wise which begs the question, why try to modify the outer core?"

Additional Sample F - RG 2.535"/Differential .055" - "This is the only additional sample with the same core shape as the original sample. If you look closely, you can see that there were modifications made to this outer core as well. The RG values show us this ball should be very similar to the original sample performance wise which begs the question, why try to modify the outer core?"

The USBC Equipment Specifications team has developed a battery of tests to make sure every bowling ball that makes it to the consumer market is legal based on USBC rules.

The USBC Equipment Specifications team has developed a battery of tests to make sure every bowling ball that makes it to the consumer market is legal based on USBC rules."Sometimes people ask what they get for their USBC membership, and this is one of those behind-the-scenes things we do for our members," USBC Managing Director of National Governing Body Neil Stremmel said. "The tests that we do on new bowling balls help protect our members from wasting their hard-earned money on bowling balls that could potentially not work as advertised."

An example of why tests on new bowling balls is so important recently was uncovered at USBC Headquarters earlier this year when an international manufacturer submitted balls that did not meet proper standards and was not approved.

The manufacturer submitted several samples of the new ball, all of which were identical on the outside, but the cores of the balls were where the problems began.

After performing tests on the balls and coming back with head-scratching results, the USBC Equipment Specifications team cut each of the bowling balls in half and the results were shocking.

The same ball had two main core shape differences and five modified versions of the two main cores. The serial numbers on the balls were sequential, which means the balls should have come out of the production line in order.

"Had this ball not been further scrutinized, there would be no way to know what the end user was getting," Stremmel said. "The ball also would have been subject to cracking and core separation with the large void in the core.

"This is just one example of how we protect USBC members by doing what we do. Nobody wants to spend $200 or more on a ball and not know if they're getting a quality product, or a product that is similar to all of the other balls of the same model."

Stremmel said that without the approval process the danger is that a bowler could purchase this ball and wanted to compliment it with one like it, which would be impossible. The ability to consistently manufacture the bowling ball the same way each time is critical.

"If a bowler went out and bought this ball and their friends liked it and wanted one that reacts similar, it would be impossible and they would end up wasting their money," Stremmel said. "Or worse yet, if someone were new to bowling and purchased a bowling ball like this that would not react properly, they may quit the sport."

USBC Research Technician Jason Milligan said noticing the difference between the balls is important because it assures there will be consistency in the products available to consumers.

Milligan offered the following descriptions that go along with photos of the inside of each ball that was tested.

Original Sample - RG 2.534"/Differential .054" - "This ball has a large void in the center of the inner core, which is not allowed. Other than that, the core shape has not been altered, and this ball would otherwise be allowed. All manufacturing requirements can be found in the USBC Equipment Specifications Manual."

Original Sample - RG 2.534"/Differential .054" - "This ball has a large void in the center of the inner core, which is not allowed. Other than that, the core shape has not been altered, and this ball would otherwise be allowed. All manufacturing requirements can be found in the USBC Equipment Specifications Manual." Additional Sample A - RG 2.550"/Differential .049" - "This ball shows an entirely different inner core shape from the original sample. This shape has a higher RG and lower differential, which should result in not as much hook potential with all other things being considered equal. Also, there have been modifications to the outer core by drilling into it and filling it with a different density material."

Additional Sample A - RG 2.550"/Differential .049" - "This ball shows an entirely different inner core shape from the original sample. This shape has a higher RG and lower differential, which should result in not as much hook potential with all other things being considered equal. Also, there have been modifications to the outer core by drilling into it and filling it with a different density material." Additional Sample B - RG 2.573"/Differential .049" - "This inner core shape is similar to Additional Sample A, but with a larger modification to the outer core. The modifications also raised the Low RG values, which should result in the ball not picking up a roll as soon as the other two balls mentioned."

Additional Sample B - RG 2.573"/Differential .049" - "This inner core shape is similar to Additional Sample A, but with a larger modification to the outer core. The modifications also raised the Low RG values, which should result in the ball not picking up a roll as soon as the other two balls mentioned." Additional Sample C - RG 2.568"/Differential .044" - "This inner core shape is similar to Additional Samples A and B but only has one modification to the outer core. This ball would have a little less hook potential compared to Additional Samples A and B and significantly less when compared to the original sample."

Additional Sample C - RG 2.568"/Differential .044" - "This inner core shape is similar to Additional Samples A and B but only has one modification to the outer core. This ball would have a little less hook potential compared to Additional Samples A and B and significantly less when compared to the original sample." Additional Sample D - RG 2.575"/Differential .041" - This ball appears to have the same inner core shape as Additional Samples A, B and C. However, this core doesn't show any modification to the outer core and with the .041" of differential it would have the least amount of hook potential of any of the samples so far."

Additional Sample D - RG 2.575"/Differential .041" - This ball appears to have the same inner core shape as Additional Samples A, B and C. However, this core doesn't show any modification to the outer core and with the .041" of differential it would have the least amount of hook potential of any of the samples so far." Additional Sample E - RG 2.590"/Differential .049" - "This ball has the same inner core shape as the other additional samples listed so far but with the largest modification to the outer and inner core. In fact, the material used to fill in the holes drilled for modification hardened before it could fill the holes completely resulting in voids, which are not allowed. This ball has the highest Low RG value of any of the balls tested and would have the most delayed reaction of any of the balls shown."

Additional Sample E - RG 2.590"/Differential .049" - "This ball has the same inner core shape as the other additional samples listed so far but with the largest modification to the outer and inner core. In fact, the material used to fill in the holes drilled for modification hardened before it could fill the holes completely resulting in voids, which are not allowed. This ball has the highest Low RG value of any of the balls tested and would have the most delayed reaction of any of the balls shown." Additional Sample F - RG 2.535"/Differential .055" - "This is the only additional sample with the same core shape as the original sample. If you look closely, you can see that there were modifications made to this outer core as well. The RG values show us this ball should be very similar to the original sample performance wise which begs the question, why try to modify the outer core?"

Additional Sample F - RG 2.535"/Differential .055" - "This is the only additional sample with the same core shape as the original sample. If you look closely, you can see that there were modifications made to this outer core as well. The RG values show us this ball should be very similar to the original sample performance wise which begs the question, why try to modify the outer core?"